Podrobnosti produkta

Podroben opis izdelka

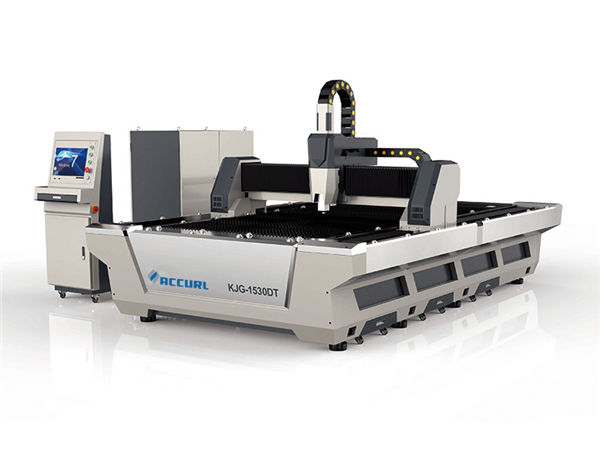

| Ime izdelka: | Laserski stroj za rezanje plošč in cevi z vlakni | Tip laserja: | Fiber laser |

|---|---|---|---|

| Laserska moč: | 800w/1000w/2000w/4000w | Garancija: | 12 mesecev |

| Poprodajne storitve: | Servis inženirjev v tujini | Utež: | 3000 kg |

| Programska oprema za nadzor: | Cypcut | CNC ali ne: | DA |

| Primerno gradivo: | Metal Tube And Metal Plate | Napajanje: | AC380V±5% 50/60Hz (3 Phase) |

Opis izdelkov

Tube Laser Cutting Machine P2060A Main Features

Rise Laser tube laser cutting machine P2060A adopts most sophisticated fiber laser N-light / IPG, combining self-design Gantry CNC machine and high strength welding body. After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability with imported high precision and high speed, linear guide drive,high-speed servo motor.Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity. It is mainly for cutting tube under 20mm metal in high speed and high precision. Fiber laser has a series of advantages, such as high beam quality, high brightness, high conversion rates, maintenance-free, stable and reliable operation of low cost and small size, etc. Air-assisted cutting is the most advanced level of laser cutting, which is particularly suitable for stainless steel,carbon steel,alloy,brass,copper, titanium and other metal materials precision cutting. It is widely used in metal products,bicycle, metal furniture,fitness equipment,sports equipment,farm machinery,display shelf,fire control.

Lastnosti stroja

1. Design of double electric chucks and double servo motors, apply to cut tube as round ,square, Rectangular tube, oval tube, I-beam, etc.

2. Pneumatic rolling wheel supporting design to ensure the turning stability during cutting.

3. High-performance laser source and stable operating system that make the best cutting effect.

4. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

5. The machine can be used for cutting a variety of metals with excellent and stable cutting quality.

6. With a specialized CAD / CAM automatic programming software and automatic nesting software, it is possible to maximally g save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Tehnični parametri

Fiber laser power : 800W, 1000W, 1500W, 2000W, 3000W 4000W (Optional)

Delovna velikost: 3000 * 1500mm

Točnost pozicioniranja X in Y: + -0,05 mm

Način prenosa: uvoz Nemčija Atlanta visoko natančno prestavo in stojalo z dvojnim pogonskim regalom z laserskim rezalnim strojem

| Laserska moč | 800W 1000W 2000W 3000W |

| Laserski vir | IPG/N-LIGHT Maxphotonics fiber laser resonator |

| Pipe/Tube processing (Φ x L) | Φ=20-300mm, L=6m,8m,12m(Φ=20-300mm for option; L>6m for option) |

| Pipe/Tube category | Round, square, rectangular, oval, waist round, etc |

| Rotate speed | 120 turn/minute |

| CNC control | Cypcut / Germany PA HI8000 |

| Laser head | Switzerland Raytools |

| Napajanje | AC380V±5% 50/60Hz (3 phase) |

| Total electric power | 22KW |

| Natančnost položaja | ± 0,03 mm / m |

| Ponovite natančnost položaja | ± 0,02 mm |

| Maximum position speed | 70m / min |

| Pospešek | 1g |

| Drawing programming mode | Solidworks,Pro/e,UG, etc import directly |

| Teža stroja | 6.5-7.5T |

Prednost stroja za lasersko rezanje z vlakni

1. Odlična kakovost poti: Manjša laserska pika in visoka delovna učinkovitost, visoka kakovost.

2. Velika hitrost rezanja: hitrost rezanja je 2-3 krat večja od iste moči stroj za lasersko rezanje CO2.

3. stabilen tek: sprejeti vrhunske laserske laserje za uvozna vlakna, stabilne zmogljivosti, ključni deli lahko dosežejo 100.000 ur;

4. Visoka učinkovitost za fotoelektrično pretvorbo: Primerjajte s strojem za lasersko rezanje s CO2, stroj za lasersko rezanje z vlakni ima trikratno učinkovitost fotoelektrične pretvorbe.

5. Nizki stroški: prihranite energijo in zaščitite okolje. Stopnja fotoelektrične pretvorbe znaša do 25-30%. Nizka poraba električne energije je le približno 20% -30% tradicionalnega CO2 laserskega rezalnega stroja.

6. Nizko vzdrževanje: prenos vlaken ni potreben odsev leče, razen stroškov vzdrževanja;

7. Enostavne operacije: prenos vlaken, brez nastavitve optične poti.

Podrobnosti o stroju

Pipe Automatic Bundle Loader features

1.Automatic bundle loader for option which saves labor and loading time, achieve mass production purpose

2.Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention.

3.Other shapes pipe can be semi-automatic feeding artificially.

4.Max Loading Bundle 800*800mm

5.Max Loading Bundle Weight 2500kg

6.The tape support frame for easy removal

7.Bundles of tubes lifting automatically

8.Automatic separation and automatic alignment

9.Robotic arm stuffing and feeding accurately

Automatic collecting device

1. Automatic elevating support, receive tube and scrap into the basket

2. Visual scale support can adjust support diameter quickly according to pipe diameter

3. Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swinging

Lift adjustable support system

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe.

Integration bed

1.As a whole plate welded bed, the whole length of 8 meters.

2.Integration bed can better ensure concentricity of equipment, vertical, precision installation fast and efficient.

3.The whole structure is compact precision.

3D user interface

1. Intuitive interface, better compatibility with Solidworks, Pro / e, UG software, convenient and easy to operate.

2. radical departure from the traditional CNC operating software code programming style complex method of operation.

3. Reduce the operator's requirements.

Online diagnostic function

CypTube have received servo feedback function cutting head, laser and other components, is available online diagnose the failure point device.

Uporaba izdelka

Uporaba: lahko razreže cevi, cevi in različne posebne oblike za rezanje cevi.

Premer za cev: 20-200mm

Dolžina reza: 6m / 4m itd

Debelina reza z izvorom vlaken 500W: 3 mm nerjaveče jeklo, 6 mm ogljikovo jeklo, 2 mm baker, 2 mm aluminij itd, 2,5 mm pocinkana plošča itd.