Podrobnosti produkta

Potrdilo: CE, FDA, IOS9001

Pogoji plačila in pošiljanja:

Najmanjša količina naročila: 1 set

Cena: USD

Podrobnosti o embalaži: Standardna embalaža za les

Čas dostave: 30-45 dni

Pogoji plačila: T / T, Western Union, MoneyGram, L / C, D / P

Sposobnost ponudbe: 100 kompletov na mesec

Podroben opis izdelka

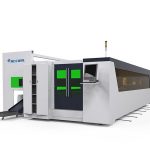

| Model: | RL-P5050-500 | Laserska moč: | 500W |

|---|---|---|---|

| Laser Vir: | Max / Raycus / Ipg | Največja velikost obdelave: | 500*500mm// 600*600mm |

| Največja obratovalna hitrost: | 800 mm / s | Nadzorni sistem: | Cypcut |

| Debelina rezanja materiala: | 0,2-30 mm | Napajanje z električno energijo: | AC380V 50Hz / 5KW |

| Natančnost pozicioniranja: | ± 0,05 mm / 500 mm | HS koda: | 8456110090 |

| Prevozni paket: | Leseni karton | Utež: | 1100KG |

| Natančnost ponovitve položaja: | ± 0,05 mm / 500 mm | Tip laserja: | Fiber laser |

Materiali za uporabo

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Machine parameters for laser generator

| Postavka | Parametri |

| Laserski tip | Fiber laser |

| Moč | 500W/1000W/1500W/2000W/3000W/4000W/6000W |

| Dolžina vala | 1070-1080nm |

| Učinkovitost elektro-optične pretvorbe | 25-30% |

| Pot XYZ | 3025mm / 1525mm / 100mm |

| Material Debelina rezanja | 0,2-8 mm |

| Rezanje širine šiva | 0,1-0,2 mm |

| Ponovite natančnost položaja | ± 0,05 mm / 500 mm |

| Natančnost pozicioniranja | ± 0,05 mm / 500 mm |

| Največja hitrost premikanja | 60000 mm / min |

| Največja hitrost nogometa | 25m / min |

| Največja teža obremenitve | 500kg |

| Teža stroja | 2300kg |

| Potrebna moč | 220V 50Hz / 60Hz |

| Velikost stroja (L * Š * V) | 4500mm * 2450mm * 1700mm |

Configuration of Fiber Laser Cutter

| Opis | Qty | Original | Blagovna znamka | |

| 1 | Fiber laser source (500W/800W) | 1SET | Kitajska | MAX |

| 2 | Laserska rezalna glava | 1PC | Switzerland | RAYTOOLS |

| 3 | Strojna postelja in dodatki | 1SET | Kitajska | |

| 4 | Electric control | 1SET | OMRON, Schneider | |

| 5 | Gas circuit control | 1SET | Japonska | SMC |

| 6 | Natančno stojalo | Each 3SETS | Kitajska | |

| 7 | Natančna linearna vodilna tirnica | Each 3SETS | Tajvan | PMI |

| 8 | Planetary Gear | 3SET | Kitajska | |

| 9 | Strojni dodatki za posteljo | 1SET | Kitajska | |

| 10 | Digitalni sistem rezanja | 1SET | ZDA | AHEADCUT |

| 11 | Industrial control computer | 1SET | Kitajska | AHEADCUT |

| 12 | Communication servo and driver | 4SETS | Kitajska | |

| 13 | Cooling Unit | 1SET | Kitajska | |

| 14 | Oprema za recikliranje odpadkov | 1SET | Kitajska |

Equipment Work and Environmental Requirements

| Requirement | |

|

1 | Power supply: regulated stable power supply: (recommended) (1)rated output voltage: 220 v (2) voltage frequency: 50 hz (3) the stability of the two phase voltage + 5% (4) the output voltage adjustment rate: < 2% |

| 2 | Cutting with auxiliary gas: Clean, dry compressed air and high purity oxygen (O2) and nitrogen (N2) ,purity no less than 99.9% purity |

| 3 | Cutting material Sheet material is even, smooth;Clean the surface |

| 4 | The compressed air supply device (1) the rated pressure: 14 bar (2)Capacityt: 1 m3 |

Parameter Teorija rezanja

| Moč (W) | Material | Debelina (mm) | Hitrost rezanja (m / min) | Plin |

| 800 | Nerjaveče jeklo | 1 | 8-9 | N2 |

| 2 | 5-6 | N2 | ||

| 3 | 1.8-2 | N2 | ||

| 4 | 1.2-1.3 | N2 | ||

| 800 | Ogljikovo jeklo | 1 | 8-10 | O2 |

| 2 | 4-5 | O2 | ||

| 3 | 2.8-3 | O2 | ||

| 4 | 1.4-1.8 | O2 | ||

| 5 | 1.2-1.5 | O2 | ||

| 6 | 0.9-1.1 | O2 | ||

| 8 | 0.6-0.7 | O2 |

| Moč (W) | Material | Debelina (mm) | Hitrost rezanja (m / min) | Plin |

| 500 | Nerjaveče jeklo | 1 | 6-8 | N2 |

| 2 | 2-2.2 | N2 | ||

| 3 | 0.6-0.8 | N2 | ||

| 500 | Ogljikovo jeklo | 1 | 7-8 | O2 |

| 2 | 3.5-4 | O2 | ||

| 3 | 2.8-3.2 | O2 | ||

| 4 | 1.3-1.5 | O2 | ||

| 5 | 0.9-1.1 | O2 | ||

| 6 | 0.6-0.7 | O2 |